PRODUCTS

CONTACTS

If you are interested,please contact us by email

Telephone

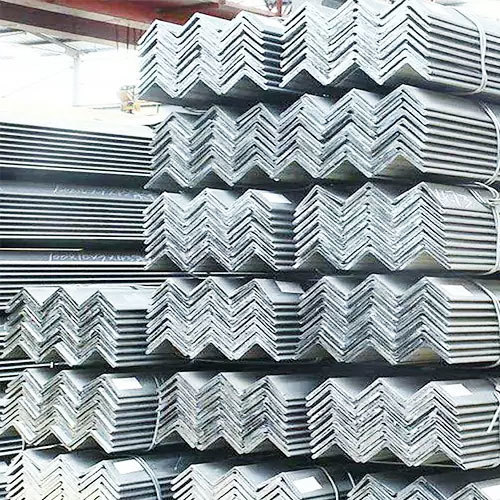

6063 aluminum alloy material.

The main alloy elements are magnesium and silicon, with excellent machining performance, excellent weldability, extrusion and electroplating, good corrosion resistance, toughness, easy to polish, color film, excellent anodic oxidation effect, is a typical extrusion alloy.

6063 aluminum alloy profile with its good plasticity, moderate heat treatment strength, good welding performance and anodic oxidation treatment, gorgeous surface color and many other advantages, is widely used in building profiles, irrigation pipes, for vehicles, platforms, furniture, elevators, fences and other tubes, bars, profiles.

The main alloy elements are magnesium and silicon, with excellent machining performance, excellent weldability, extrusion and electroplating, good corrosion resistance, toughness, easy to polish, color film, excellent anodic oxidation effect, is a typical extrusion alloy.

6063 aluminum alloy profile with its good plasticity, moderate heat treatment strength, good welding performance and anodic oxidation treatment, gorgeous surface color and many other advantages, is widely used in building profiles, irrigation pipes, for vehicles, platforms, furniture, elevators, fences and other tubes, bars, profiles.

7075-T6 aluminum alloy hardness is 150HB, belongs to the high hardness aluminum alloy.

7075T6 aluminum alloy is precision machined aluminum in the United States, one of the most commercially available alloys.

The main alloying element of 7075 series is zinc, which has strong strength, good mechanical properties and anode reaction.

7075T6 aluminum alloy is precision machined aluminum in the United States, one of the most commercially available alloys.

The main alloying element of 7075 series is zinc, which has strong strength, good mechanical properties and anode reaction.

6063 aluminum alloy material.

6063 is a low alloyed Al-Mg-Si high plastic alloy.

The main alloy elements are magnesium and silicon, with excellent machining performance, excellent weldability, extrusion and electroplating, good corrosion resistance, toughness, easy to polish, color film, excellent anodic oxidation effect, is a typical extrusion alloy.

6063 is a low alloyed Al-Mg-Si high plastic alloy.

The main alloy elements are magnesium and silicon, with excellent machining performance, excellent weldability, extrusion and electroplating, good corrosion resistance, toughness, easy to polish, color film, excellent anodic oxidation effect, is a typical extrusion alloy.

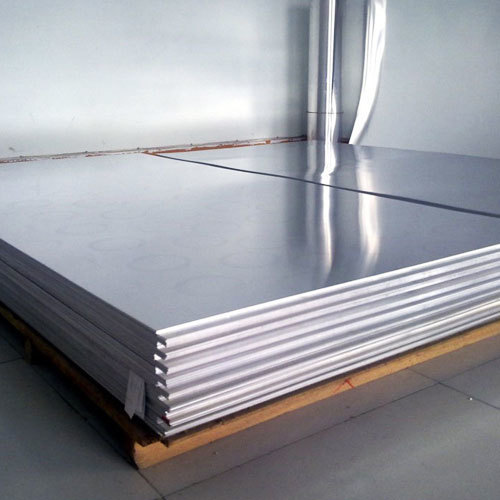

Thickness: 0.15-600mm

Port of Destination: Any port you like

Aluminium Sheets with high strength is mainly used make Fire Engine Side Panel and Dump Truck Floor in industry.

Because of its good energy absorption ability in collision experiment, engine mount, side impact beam, engine splash shield, ABS, airbag part, etc.

Port of Destination: Any port you like

Aluminium Sheets with high strength is mainly used make Fire Engine Side Panel and Dump Truck Floor in industry.

Because of its good energy absorption ability in collision experiment, engine mount, side impact beam, engine splash shield, ABS, airbag part, etc.

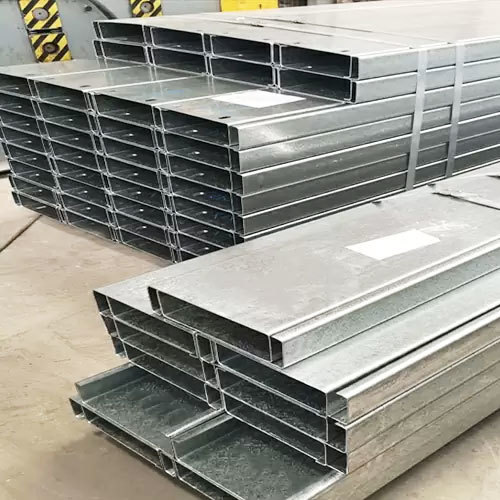

6063 aluminum alloy material.

The main alloy elements are magnesium and silicon, with excellent machining performance, excellent weldability, extrusion and electroplating, good corrosion resistance, toughness, easy to polish, color film, excellent anodic oxidation effect, is a typical extrusion alloy.

The main alloy elements are magnesium and silicon, with excellent machining performance, excellent weldability, extrusion and electroplating, good corrosion resistance, toughness, easy to polish, color film, excellent anodic oxidation effect, is a typical extrusion alloy.

6082 is a heat-treatable alloy with good formability, weldability, machinability and corrosion resistance.

It also has moderate strength and can maintain good operability after annealing.

It is mainly used in mechanical structure, including bars, plates, pipes and profiles.

This alloy has similar but not identical mechanical properties to alloy 6061, and its -T6 state has higher mechanical properties.

It also has moderate strength and can maintain good operability after annealing.

It is mainly used in mechanical structure, including bars, plates, pipes and profiles.

This alloy has similar but not identical mechanical properties to alloy 6061, and its -T6 state has higher mechanical properties.

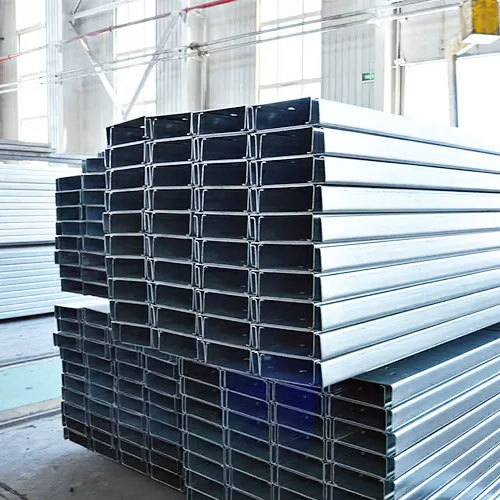

6063 aluminum alloy material.

The main alloy elements are magnesium and silicon, with excellent machining performance, excellent weldability, extrusion and electroplating, good corrosion resistance, toughness, easy to polish, color film, excellent anodic oxidation effect, is a typical extrusion alloy.

The main alloy elements are magnesium and silicon, with excellent machining performance, excellent weldability, extrusion and electroplating, good corrosion resistance, toughness, easy to polish, color film, excellent anodic oxidation effect, is a typical extrusion alloy.

7075 aluminum alloy is a cold - treated forging alloy, high strength, far better than mild steel.

7075 is one of the strongest alloys commercially available. Under heat treatment, can achieve very high strength characteristics.

7075 materials are generally added a small amount of copper, chromium and other alloys, the department of 7075-T651 aluminum alloy is particularly top grade, known as the best aluminum alloy products, high strength, far better than any mild steel. The alloy also has good mechanical properties and anode reaction.

7075 is one of the strongest alloys commercially available. Under heat treatment, can achieve very high strength characteristics.

7075 materials are generally added a small amount of copper, chromium and other alloys, the department of 7075-T651 aluminum alloy is particularly top grade, known as the best aluminum alloy products, high strength, far better than any mild steel. The alloy also has good mechanical properties and anode reaction.

The main alloying elements in 6061 alloy are magnesium and silicon, which have moderate strength, good corrosion resistance, weldability and good oxidation effect.

Widely used in various industrial structural parts requiring a certain strength and high antibiotic corrosion, its main chemical composition: Cu:0.15-0.4; Si: 0.4-0.8; Fe: 0.7 -; Mn: 0.15; Mg: 0.8-1.2; Zinc: 0.25; Cr: 0.04-0.35; Ti: 0.15 -; 6061 aluminum plate its state T6 and T651 difference is that in general, T6 internal stress will be relatively large, processing will be deformed, the most suitable for processing state should be T651, he is on the basis of T6 tensile, eliminate internal stress.

Widely used in various industrial structural parts requiring a certain strength and high antibiotic corrosion, its main chemical composition: Cu:0.15-0.4; Si: 0.4-0.8; Fe: 0.7 -; Mn: 0.15; Mg: 0.8-1.2; Zinc: 0.25; Cr: 0.04-0.35; Ti: 0.15 -; 6061 aluminum plate its state T6 and T651 difference is that in general, T6 internal stress will be relatively large, processing will be deformed, the most suitable for processing state should be T651, he is on the basis of T6 tensile, eliminate internal stress.

Thickness: 0.15-150mm

Port of Destination: Any port you like

Aluminium Sheets with high strength is mainly used make Fire Engine Side Panel and Dump Truck Floor in industry.

Because of its good energy absorption ability in collision experiment, engine mount, side impact beam, engine splash shield, ABS, airbag part, etc.

Port of Destination: Any port you like

Aluminium Sheets with high strength is mainly used make Fire Engine Side Panel and Dump Truck Floor in industry.

Because of its good energy absorption ability in collision experiment, engine mount, side impact beam, engine splash shield, ABS, airbag part, etc.

Aluminium Pipe can be produced in two types drawn and extruded aluminum pipe.

Extruded aluminum pipe is stocked in both seamless and structural (port-hole die).

Aluminium pipe is used in pressure or structural application.

These Aluminium Pipe are light weight, excellent corrosion resistance, and the ability to transmit heat rapidly are only a few of the benefits of aluminum pipes.

Extruded aluminum pipe is stocked in both seamless and structural (port-hole die).

Aluminium pipe is used in pressure or structural application.

These Aluminium Pipe are light weight, excellent corrosion resistance, and the ability to transmit heat rapidly are only a few of the benefits of aluminum pipes.

6082 is a heat-treatable alloy with good formability, weldability, machinability and corrosion resistance.

It also has moderate strength and can maintain good operability after annealing. It is mainly used in mechanical structure, including bars, plates, pipes and profiles.

This alloy has similar but not identical mechanical properties to alloy 6061, and its -T6 state has higher mechanical properties.

It also has moderate strength and can maintain good operability after annealing. It is mainly used in mechanical structure, including bars, plates, pipes and profiles.

This alloy has similar but not identical mechanical properties to alloy 6061, and its -T6 state has higher mechanical properties.

6061 alloy are magnesium and silicon, which have moderate strength, good corrosion resistance, weldability and good oxidation effect.

Widely used in various industrial structural parts requiring a certain strength and high antibiotic corrosion, its main chemical composition: Cu:0.15-0.4; Si: 0.4-0.8; Fe: 0.7 -; Mn: 0.15; Mg: 0.8-1.2; Zinc: 0.25; Cr: 0.04-0.35; Ti: 0.15 -; 6061 aluminum plate its state T6 and T651 difference is that in general, T6 internal stress will be relatively large, processing will be deformed, the most suitable for processing state should be T651, he is on the basis of T6 tensile, eliminate internal stress.

Widely used in various industrial structural parts requiring a certain strength and high antibiotic corrosion, its main chemical composition: Cu:0.15-0.4; Si: 0.4-0.8; Fe: 0.7 -; Mn: 0.15; Mg: 0.8-1.2; Zinc: 0.25; Cr: 0.04-0.35; Ti: 0.15 -; 6061 aluminum plate its state T6 and T651 difference is that in general, T6 internal stress will be relatively large, processing will be deformed, the most suitable for processing state should be T651, he is on the basis of T6 tensile, eliminate internal stress.