PRODUCTS

CONTACTS

If you are interested,please contact us by email

Telephone

1. Power industry -- fan blades, burner pipelines, feeder and hopper lining, crusher parts, coal grinder parts, ash pipes, air

handling systems and conveyors;

2. Have spentIron and steel industry - hopper lining, grille, feeder and base, dump truck, hopper, pipe, pump shell, crusher

parts, slag trough, various chassis, vibrating screen;

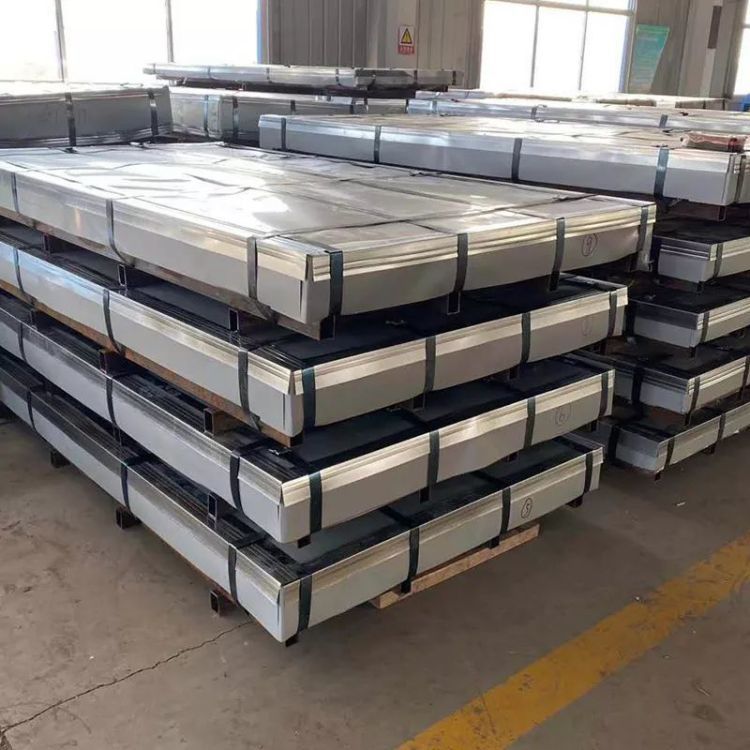

Galvalumed sheet, with 55% aluminum zinc alloy coating on the surface. The surface of the Galvalumed sheet presents a unique smooth, flat and gorgeous star, and the basic color is silver white. The special coating structure makes it have excellent corrosion resistance. The normal service life of the Galvalumed sheet can reach 25a, and the heat resistance is very good, which can be used in the high temperature environment of 315 ℃; The coating has good adhesion with the paint film, has good processing performance, and can be punched, sheared, welded, etc; The surface conductivity is very good.

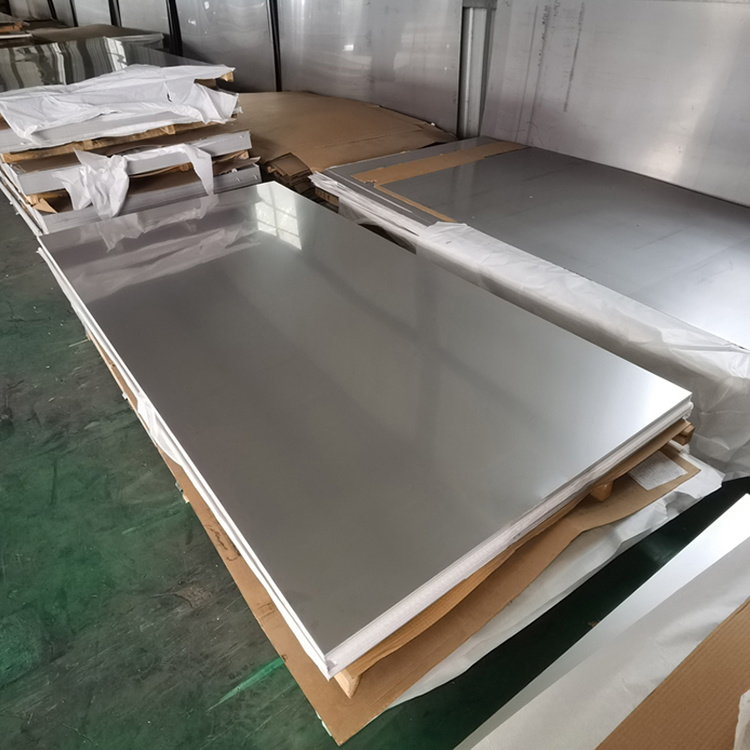

Stainless steel coils are imported and domestic products, divided into hot-rolled and cold-rolled. According to the needs of different users, we can also order a variety of special-shaped steel materials.In order to ensure that the yield strength, tensile strength, elongation and hardness of various stainless steel coils meet the requirements, the stainless steel coils must undergo heat treatment such as annealing, solution treatment, and aging treatment before delivery.

The surface of theGalvalume Coil is a unique smooth, flat and gorgeous star, and the basic color is silver white. The special coating structure makes it have excellent corrosion resistance. The normal service life of the Galvalume Coil can reach 25a, and the heat resistance is very good, which can be used in the high temperature environment of 315 ℃; The coating has good adhesion with the paint film, has good processing performance, and can be punched, sheared, welded, etc; The surface conductivity is very good.

The thickness of the radiation-proof lead plate is closely related to its protective effect. Common thicknesses range from 0.5mm to 3mm, depending on the type, intensity and frequency of the ray. For example, medical ray chambers typically use lead plates with a thickness of 0.5 mm to 1 mm, while lead plates with a thickness of 2 mm to 3 mm may be required in industrial ray detection or nuclear facilities.

The main features of lead plates include high density, good corrosion resistance, low melting point and soft and easy processing. Lead plates are made of metal lead rolling, and have the characteristics of high density, good corrosion resistance, low melting point and soft and easy to process. These characteristics make lead plates excellent in blocking radioactive rays and can effectively protect people from radiation damage.

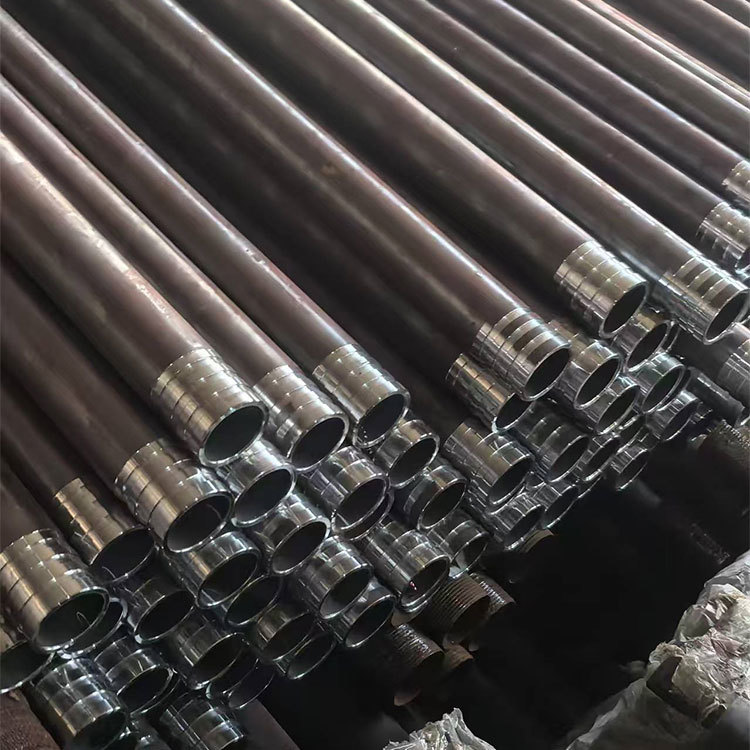

Grouting pipe is a tool used to inject cement slurry or sand slurry liquid into deep underground layers to solidify or strengthen the foundation.9 It mainly consists of the main part that conveys the slurry liquid, the valve control part, the sealing part, and the connecting part.9 The grouting pipe can effectively control the rise of the groundwater level through the impact force of the high-pressure water by ejecting water liquid out of the injection holes of the injection pipe and stabbing it into the ground.

Grouting pipe is a tool used to inject cement slurry or sand slurry liquid into deep underground layers to solidify or strengthen the foundation.9 It mainly consists of the main part that conveys the slurry liquid, the valve control part, the sealing part, and the connecting part.9 The grouting pipe can effectively control the rise of the groundwater level through the impact force of the high-pressure water by ejecting water liquid out of the injection holes of the injection pipe and stabbing it into the ground.

Grouting pipe is a tool used to inject cement slurry or sand slurry liquid into deep underground layers to solidify or strengthen the foundation.9 It mainly consists of the main part that conveys the slurry liquid, the valve control part, the sealing part, and the connecting part.9 The grouting pipe can effectively control the rise of the groundwater level through the impact force of the high-pressure water by ejecting water liquid out of the injection holes of the injection pipe and stabbing it into the ground.